Product Description

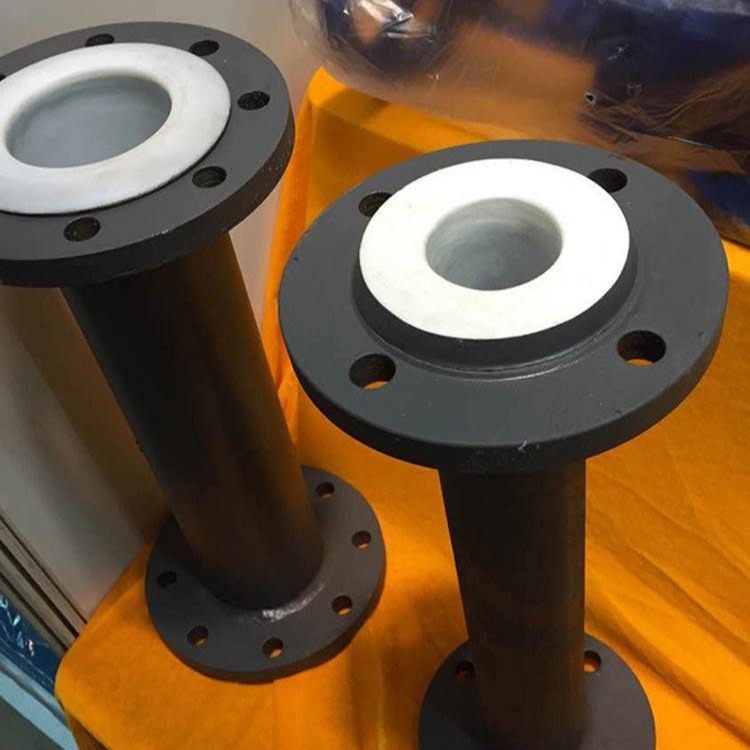

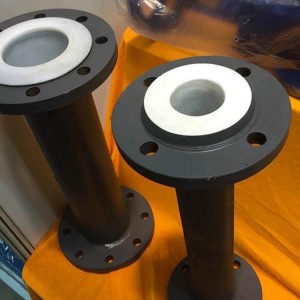

ASTM F1545-15a PTFE Lined Elbow Pipe Fitting

Product Description

Lining Material: PFA, PTFE,PVDF,FEP,ETFE etc.

Nominal diameter: DN25~DN300,1″~12″

Length: ≤6000mm (size≤DN150) ≤4000mm (size>DN150)

Temperature range: -29°C~180°C

Applicable medium:

Able to transport any concentration of acid, alkali, organic solvents, strong oxidant, toxic and volatile, flammable chemicals.

Specification Instruction:

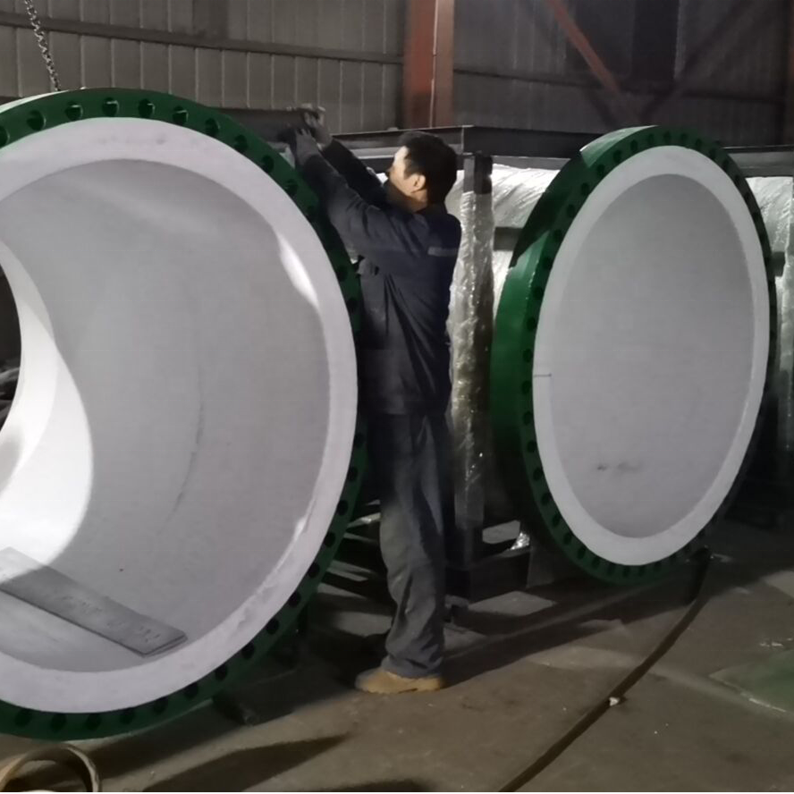

We manufactures PTFE lined pipe and fittings by compression molding, isostatic molding, injection molding, transfer molding,

hot rotomolding, ram/paste extrusion, 3D rotational molding etc. Characters as below:

• Working temperature is high at the range of -29°C-200°C; except the molten alkali metals, element fluorine and aromatic

hydrocarbon, lined products can be used in any chemical medium.

• Vacuum resistance. In the range of -29°C-150°C, it is applicable for vacuum condition. In chemical production, the vacuum

condition occurs due to cooling, longitudinal emissions, or medium backflow.

• High-pressure resistance. Within temperature working condition, it can sustain the working pressure of 3.0 MPa.

• Resistance to penetration. Adapt the high-quality PTFE, to make it of high density and enough thickness after advanced lining

processing, make it excellent antiosmosis.

• PTFE advanced lining molding process achieved the status of syn chronous hot expansion or cold shrinkage for steel components

and fluorine plastic.

• Kaxite us adopts the standard size according to HG, GB, DIN, ANSI, and JIS etc., which improves interchangeability, to provide

convenience for installation.

Data sheet

Specific Gravity: 2.14-2.19g/cm3 as per ASTM D 792 test standard.

Tensile Rate: 20.7Mpa minimum as per ASTM D 638 test standard.

Elongation Rate: 250% minimum as per ASTM D 638 test standard.

Manufacture Standard: ASTM D 4895. Operating in vacuum condition within 150°C